On August 14, recently, Marketsand Markets published on the latest market research report of the 4D print 4D print marketing materials, end users, industries and geographies--global trends and forecasting, 2019-2025. The report said, is in a commercial edge poised to 4D the print market is expected to reach $ 63 million by 2019, which walk in the forefront overall market growth of defense related applications market share will reach 55%, and by the year 2025, 4D print market will reach us $ 555.6 million. 4D print materials, Marketsand Markets expected by 2019, programmable carbon fiber market share will reach 62%, accounting for the lion's share of 4D print material market.

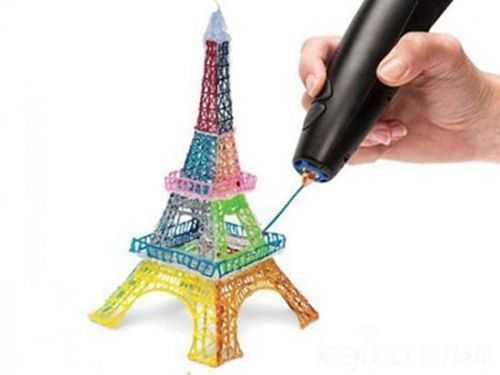

Obviously, from the concept to life with 3D printing, 4D printing also is accelerating the pace of development, market blueprint has slowly opened. Then, in the rapid development of science and technology now 4D prints as traditional manufacturing industries an opportunity to change direction and technology entrepreneurs, and what are the unique advantages? Sun Wukong s subversion of the entrepreneurial

Advantage: significantly reduce manufacturing costs

Whether modern manufacturing technology, or based on industry 4.0, new manufacturing technology of Chinese manufacturing 2025, or personality for producing products, whether manufacturing or Assembly costs are too high, even with the rising complexity of the components the same proportion.

4D supported by print technology products manufacturing, parts and product structures of how easy or difficult will become less important, because through the integration of the different components of the overall product to print, and deformable Assembly Assembly cost break, which greatly reduced the cost of manufacture of the product.

Advantage two: personalized custom cost the same

Under the current manufacturing technology and the environment, small batch order cost is in a higher position, let alone private ordering, the cost may be to art perspective.

With the involvement of 4D printing, private order cost will be synonymous with traditional batch manufacturing and even more affordable. Because in traditional manufacturing is considered to be a very complex structure, process, before the 4D, will become simplified, in particular cost will not be affected by the complexity and volatility of the part.

Advantage three: replace the manual Assembly costs

4D printed parts, assembled will not require manufacturers or users. Manufacturer according to user needs, will manufacture the products to the specified location when in place, user triggered directly to the media when it is needed, will automatically print Assembly, which replaced the current depends on the human Assembly build or dismantling, labor costs will also be released.

Advantage 4:0 inventory of production

For manufacturing companies, all merchandise that is assets, is also a core part of their cost of capital, once a sales slowdown in turnover will lead directly to reduce the rate of capital turnover, and profits.

By 4D print production will effectively alleviate the problem. Manufacturers according to the consumer product design, print, manufacture of service at any time, to "is buy is made, namely, that sells" real replaced the traditional stock sales.

Advantage five: Zoom creative space

For many designers, the most painful thing is creative very busty, reality manufacture are very skinny. Full of ideas, design engineers, as well as traditional manufacturing techniques, changed out of all recognition.

4D printing is no exaggeration to say that every designer can portray creative ideas have to be fulfilled to the letter, truly creative design value full bloom.

Advantage six: lower manufacturing professional

Current manufacturing, whether simple or complex, are to some extent to request professional and skilled production workers. Especially the manufacturing of high professional requirements, its workers ' professional skills and proficiency has put forward higher requirements, and technical training is also needed after years of training and settling, cultivating the skills drain in the middle of greater risk.

4D printing applications, significantly reducing our professional skill requirements for complex manufacturing parts and can help us to bear a considerable part of "difficult" process, so as to reduce the manufacture of the threshold and the risk of brain drain.

Advantages: the effective reduction of manufacturing

Most products are usually consists of multiple parts and assemble them, and different parts you need different equipment for its manufacture. For manufacturers, this not only occupy a larger space, input costs are also rising.

4D printing technology is completely different, it just needs a printer, according to different material and different parts form set by the user directly print the parts or the whole product. If part print, you can self drive Assembly.

Advantage eight: the rate will become a thing of the past

Traditional manufacturing enterprises is the most conventional manufacturing index to adverse productivity control, which is also a key indicator of the economic efficiency of enterprises.

In the 4D era, the term rates in the manufacturing process or towards the end of history, and decides whether the key to meet the needs of users will be transferred to the design side. Determine the eligibility of a product key elements of future that is no longer manufacturing, design, and by designer decisions.

Advantages: unlimited combination of materials

The manufacturing technology of the day, different raw materials into a single product is a difficult thing, because in the traditional manufacturing machines cutting or molding process cannot easily mix with a variety of raw materials. Despite the mixed injection of many materials have been used in some areas, but the cost and negative rates are relatively high.

4D print technology will allow this phenomenon to be changed is different. 4D printing process, we can use a variety of materials via the same device for mixing prints, whether it be plastic, metal or other synthetic material, this means a complete shape in the near future cars will be manufactured directly by way of print production.

Advantage: be perfect batch consistency

Although modern manufacturing techniques with the help of the mold to some extent, guarantee the consistency of the product, but it is difficult to obtain consistent accuracy of hundred percent protection.

4D print technology products "copy" solve. Relying on 4D printing technology, mass production is as simple as copying a digital file, and its consistency is as consistent as a digital copy. Whether in large or small quantities, 4D printing technology can effectively ensure their consistency.

This is not science fiction, or even a considerable part has been achieved in 3D printing technology. With print 4D technology continues to mature, we manufactured in the new industrial age, lifestyle is "print" rewritten.

No comments:

Post a Comment